Products

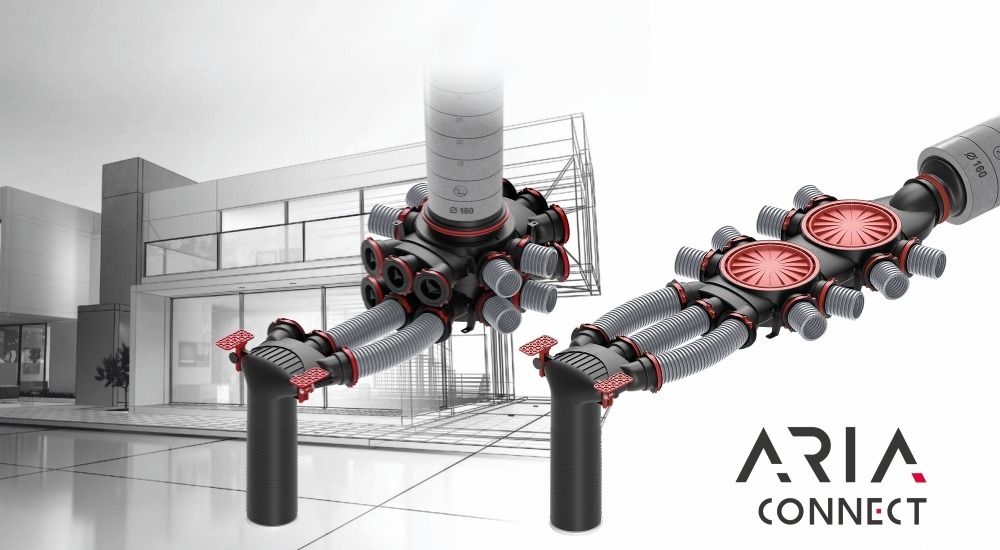

SEMI-RIGID DUCTING SYSTEM ARIA CONNECT

The idea behind the HEATPEX ARIA CONNECT semi-rigid ducting system for air distribution (3 diamiters: 63 mm, 75 mm and 90mm) is to meet the needs of Investors and Installers when it comes to a complete solution for single-family houses. The modular design of the system makes it easy to customise its parts to the specific requirements of any building.

The system components are made of extremely light yet durable plastic material ensuring reliable operation for years, without the risk of mechanical damage or corrosion.

HEATPEX ARIA’s original OneClick technology® enables very fast and convenient installation without the use of tools. Moreover, the system is one of the first on the market to meet the most restrictive ATC1 airtightness class. This ensures low operating costs and, together with the Ultra-Fresh® technology (total bactericidal activity at 99,99%), the highest air quality for the users.

ARIA CONNECT

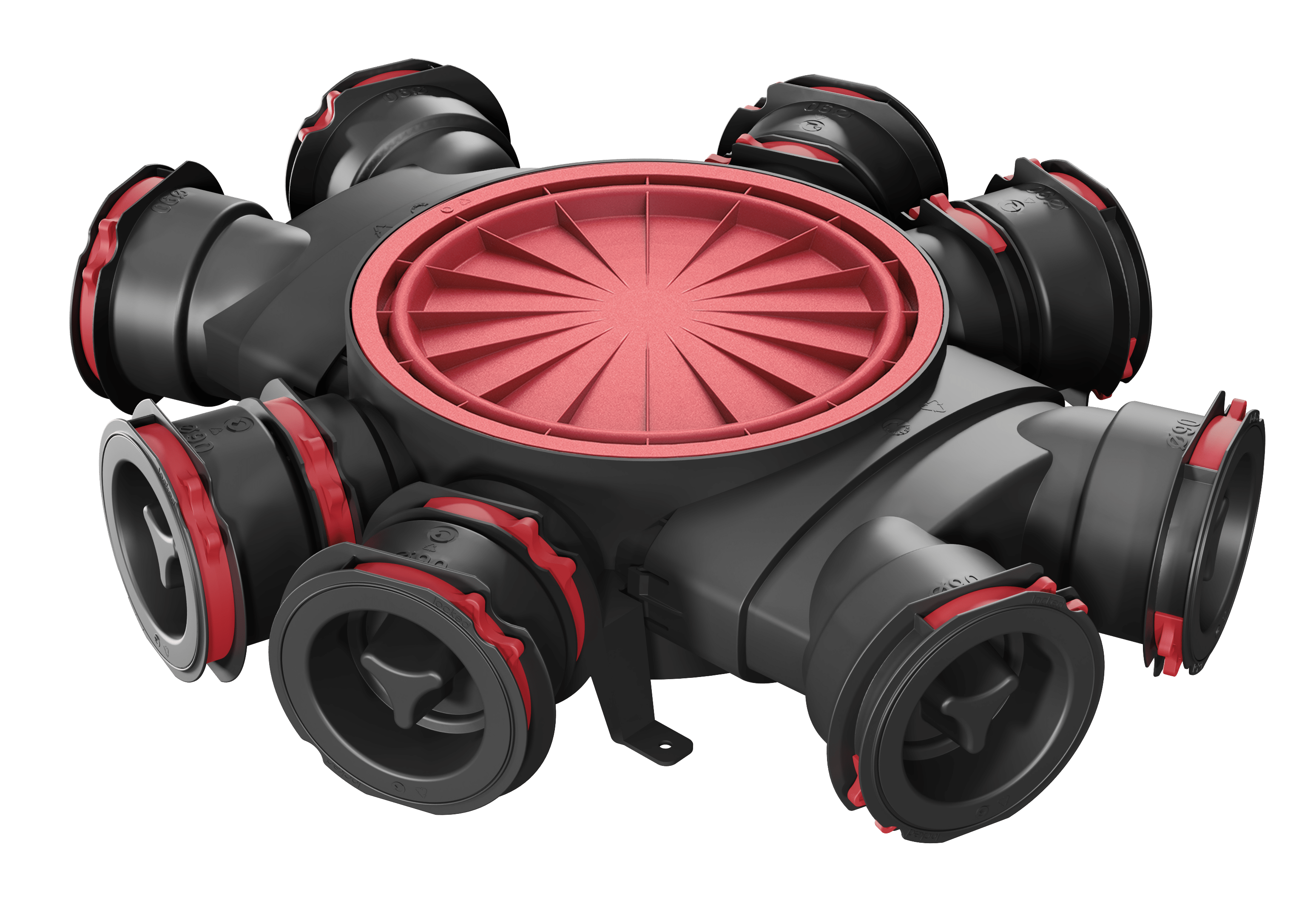

Main central connector 63mm/75mm/90 mm

Product not available in the e-shop

Main central connector 63mm/75mm/90 mm

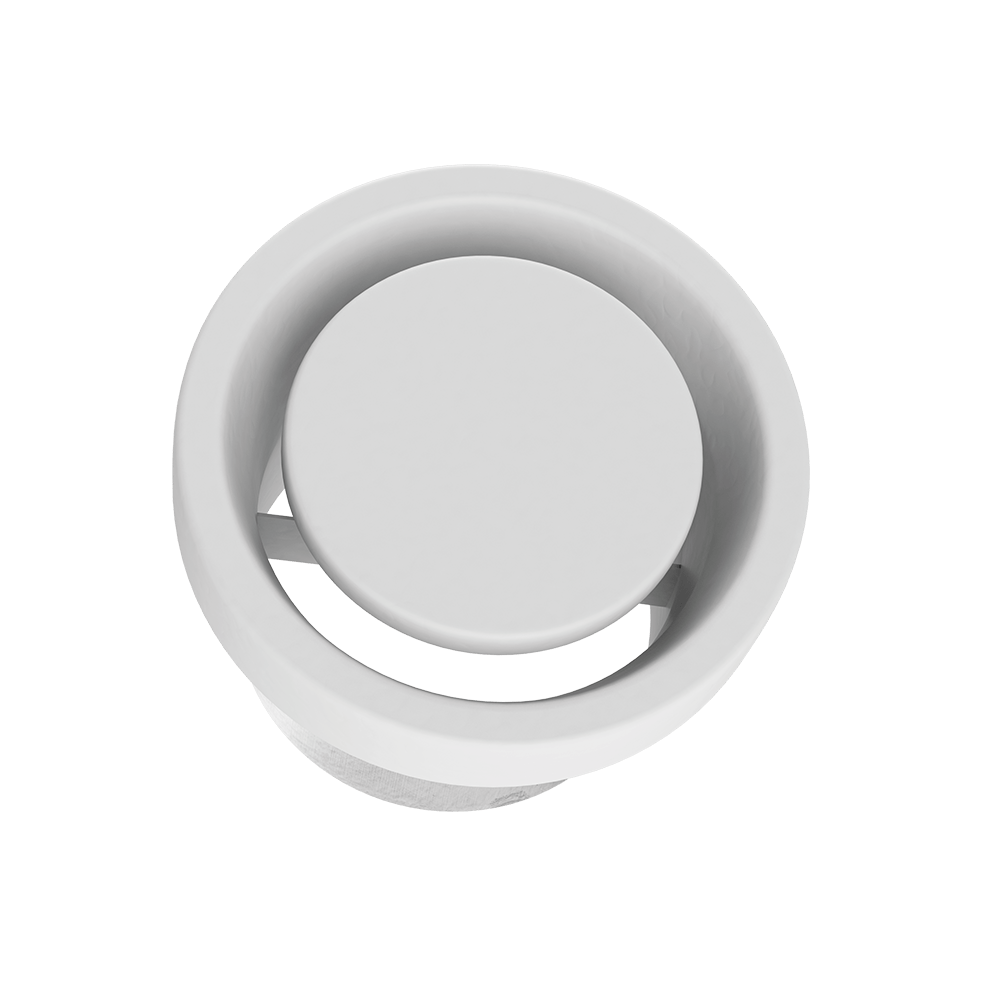

The main central connector is used to join the distribution box with supply or exhaust (insulated) pipes attached to the MVHR unit. It is installed in the central slot of the distribution box.

- Fits all ventilation systems: 63 mm, 75 mm and 90 mm.

- The connector is used to attach mass flow ducts (ARIA ADURO) for the transmission of large air flows to/from the heat recovery unit.

- The connector’s standard diameters make it possible to also connect metal (SPIRO) or other ducts.

- The connector allows for standard connections of pipe of 125, 160 and 200 mm diameter. It comes equipped with high quality gaskets for all 3 dimensions.

- Additionally you connect 150 mm and 180 mm pipes, however they require separate additional sealing. To minimise pressure losses, during installation, the smaller unused connection diameters should be cut off

- The connector has grooves that facilitate cutting off the unnecessary part.

- ARIA MVHR system is the only one on the market with the highest airtightness class – ATC 1 according to EN 17192, which guarantees quiet operation and greater energy saving

| SYSTEM | Height [mm] | Maximum diameter [mm] | Weight [kg] | Material | Catalog number |

|---|---|---|---|---|---|

| 63 mm/75 mm/ 90 mm | 171 | 249 | 0.29 | Polipropylen | 52410900100W |

Similar products

PRODUCT FILM

Semi-rigid air distribution system

HEATPEX ARIA CONNECT

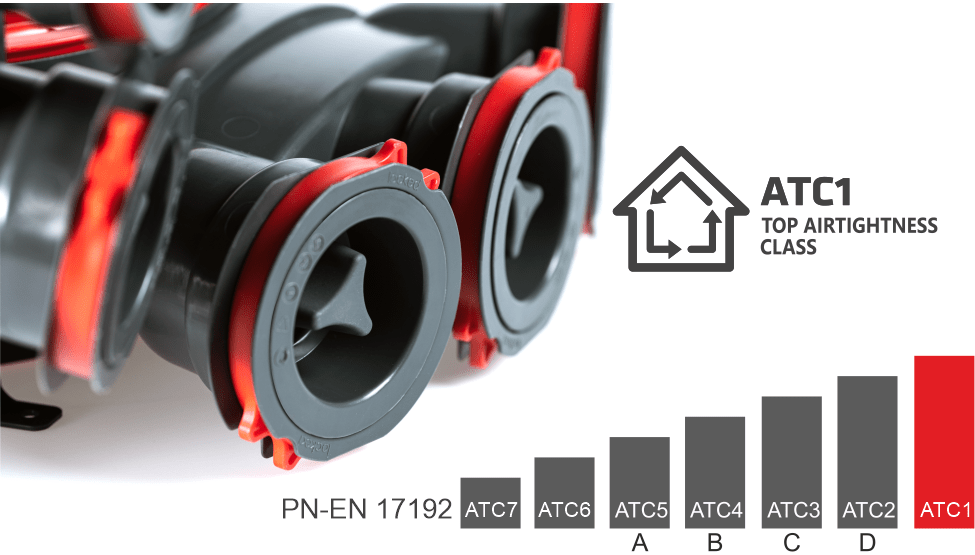

TOP AIRTIGHTNESS CLASS (ATC 1)

Quiet and energy-efficient HRV system

Through the use of appropriate materials and a patented system of connections OneClick technology between the individual parts of the system, we have achieved the top airtightness class for the system (ATC1) according to the PN-EN 17192 standard. This means that the airtightness of the ductwork in our system is three times higher than that for class D.

This is achieved with outusing any additional sealing material during the installation works. The ATC 1 airtightness class has been confirmed by tests performed by an independent laboratory.

INSTALLATION FASTER THAN EVER BEFORE

ONECLICK technology®

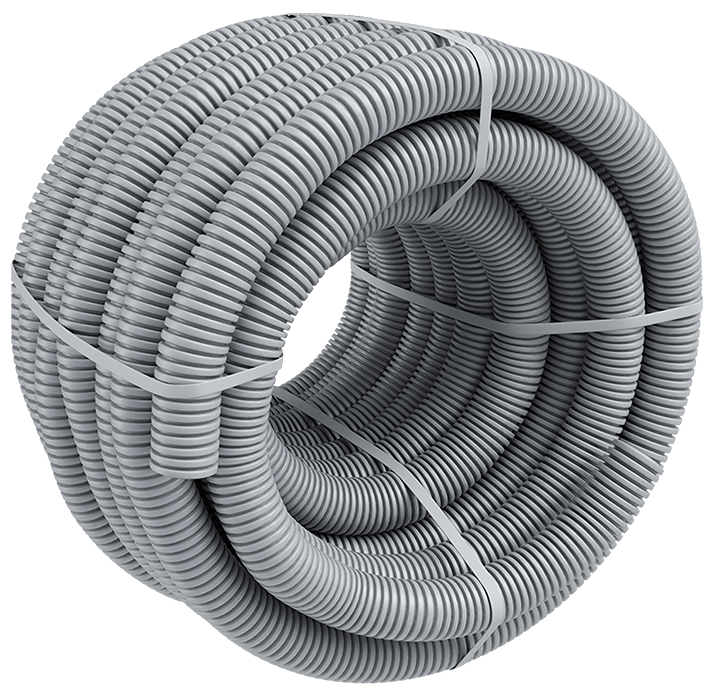

With an original system of connections – OneClick technology®, all the parts of the heat recovery system can be connected without any tools. If any modifications are needed during the installation of the system, the different parts can be disconnected easily without risk of damage.

Thanks to flexible corrugated pipes the installation is very easy. No fittings, such as pipe elbows, are required.

ANTIBACTERIAL COMES AS STANDARD

Breathe fresh and clean air at all times

The entire HEATPEX ARIA CONNECT air distribution system is treated with the Ultra – Fresh® antimicrobial additives to make the air ducts resistant to microbes (99,99% reduction). This has been confirmed by independent lab tests according to ISO 22196 standards.

The smooth inner surface of the air duct keeps dirt deposits to a minimum.

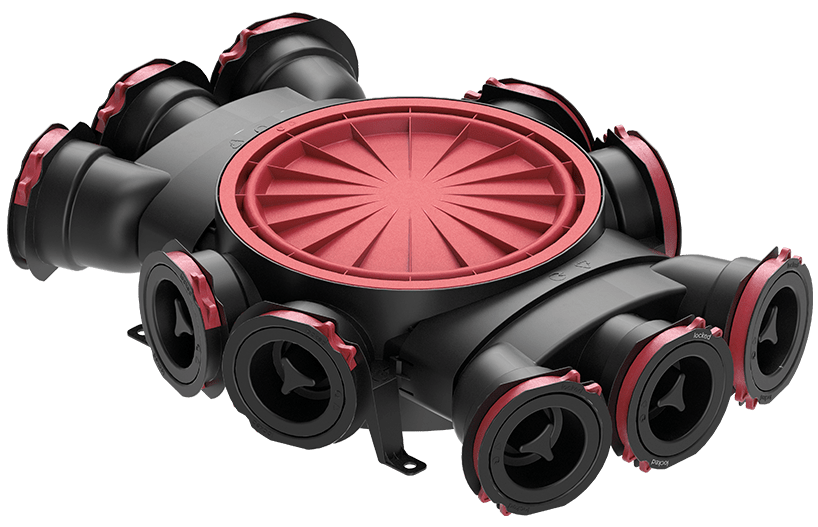

HIGHLY CUSTOMISABLE

6 basic elements only

The modular design of the system makes it easy to customise its parts to the specific requirements of any building. This helps to reduce the number of parts which are left unused, to limit the space taken by the ventilation system to a minimum and to keep the costs of the entire project as low as possible.

Distribution boxes can be connected horizontally or vertically, increasing the number of slots needed.

DISCOVER ALL ADVANTAGES OF ARIA

LOW NOISE LEVEL

The optimal air flow through different parts of the system and double wall pipes helps to reduce the level of noise generated by the flowing air, which matters especially during the night.

DURABILITY & STRENGTH

The system components are made of extremely light yet durable plastic material ensuring reliable operation for years, without the risk of mechanical damage or corrosion.

More importantly the construction material used (PP – polypropylene) is considered safe as it poses no health hazard and is 100% recyclable.

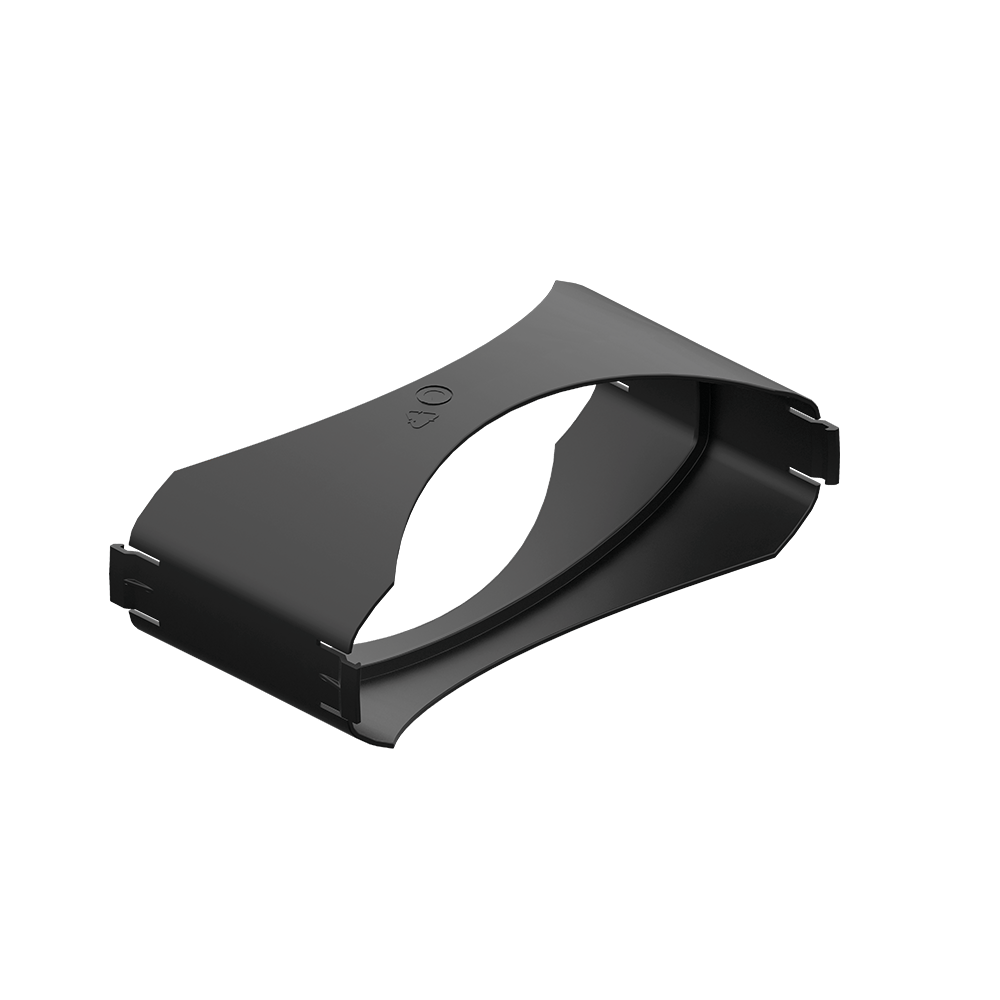

COMPACT SIZE

The small size of the HEATPEX ARIA CONNECT system allows to conceal the parts of the system in the ceiling, either in the insulation layer covered with screed or inside the plenum space if a dropped ceiling is used.

The height of the distribution box is only 10.6 cm.

LOW PRESSURE LOSS

The careful design of each single part of the system and smooth inner surface of the pipes allow to keep the system’s pressure loss low.