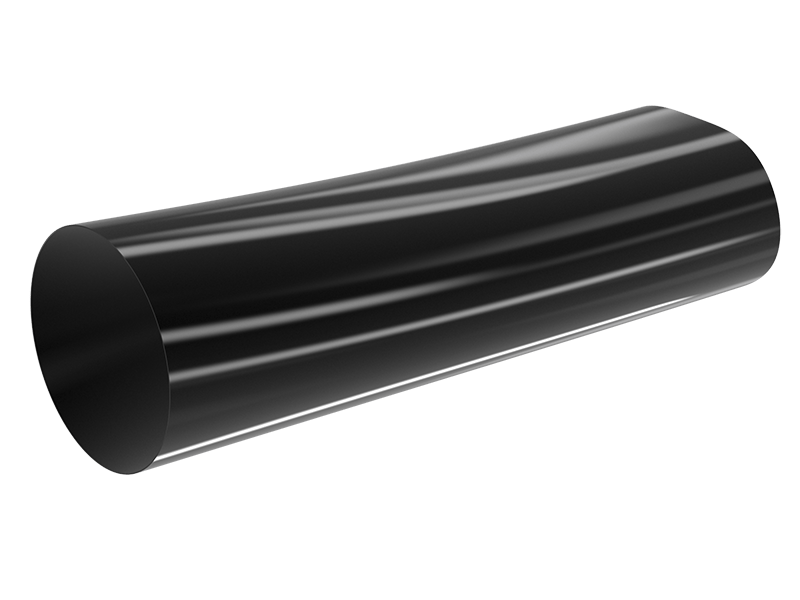

DELTA pre-insulated pipes are a safe and efficient solution for the transmission of hot and cold utility water as well as for the distribution of the heating water. They are manufactured in accordance with PN-EN 15632 -1 and 3.

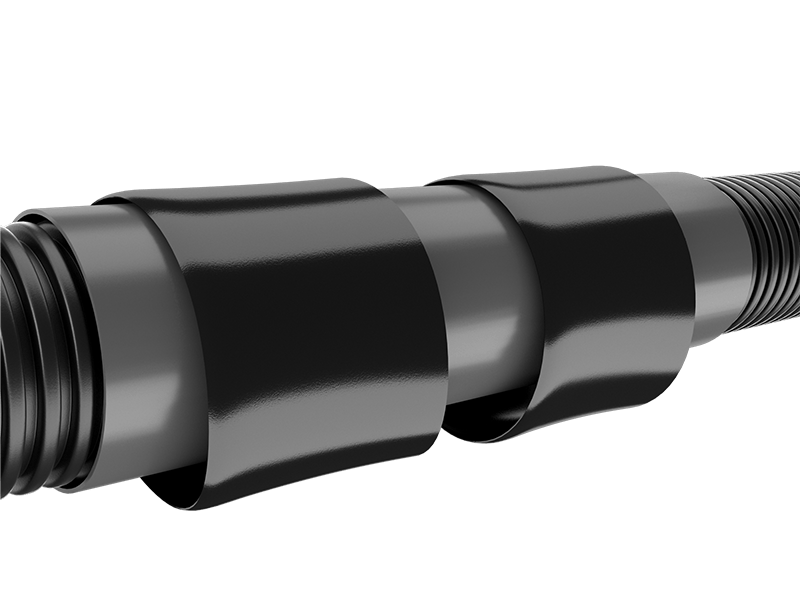

PE foam filling and corrugated polyethylene casing pipe PE-HD makes them flexible and resistant to mechanical damage during installation.

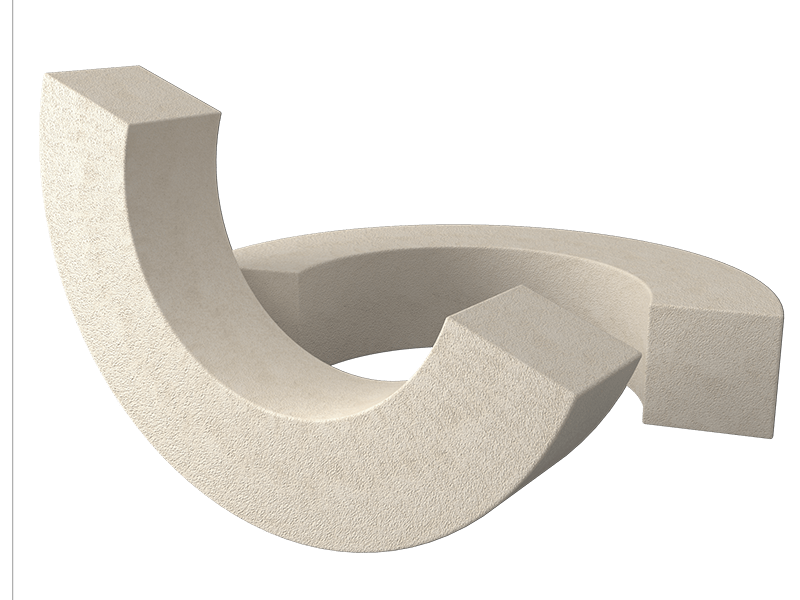

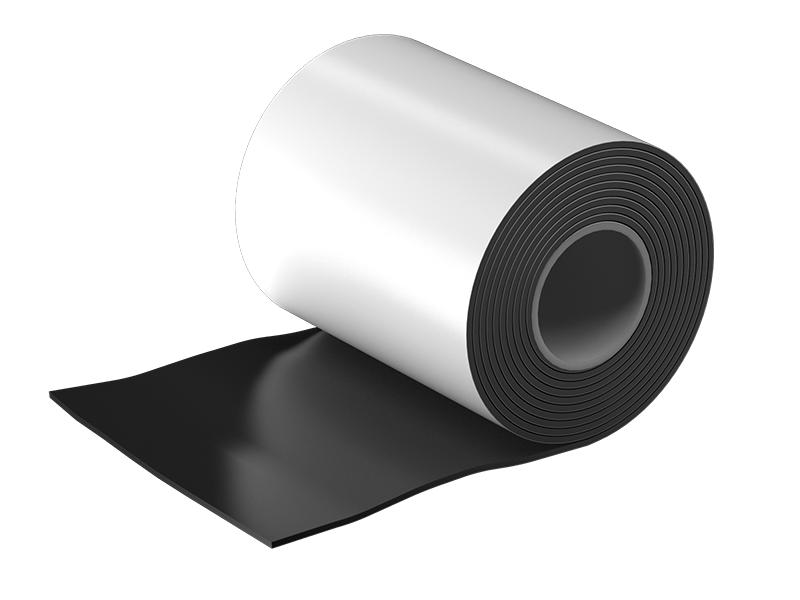

Insulation layer made of chemically cross-linked polyethylene foam of low

air conductivity minimizes heat loss during transfer of the refrigerant. Therefore, this solution is energy efficient and pro-ecological.

Similar products

PRODUCT FILM

DISCOVER ALL ADVANTAGES OF DELTA

VERSATILITY

Reliable transport of domestic hot water and heating medium to individual networks cooling, for connecting residential houses, to media for biogas plants.

Temperature resistance up to 95 °C, it is possible to use the pipe in many variants heating, with variable heat sources.

Carrier pipe available in diameters from 20 to 125 mm is a complete system with a capacity tailored to the needs of each recipient.

Pipes available in coils in max. 100m section, it is possible to order any length of pipes according to customer’s requirements.

SECURITY

Pressure resistance, both for pipes PEX-a and PE, provides a sense of security use of the pipeline throughout the entire period operation.

Dezincification resistant brass fittings, are approved by the hygienic certificate for the transfer of drinking water.

Resistance to soil pressure and additional sources loads on the backfill surface.

The outstanding service life of the installation is assured by the best components used in production DELTA system, it guarantees peace and comfort use of the pipeline for many years.

A tailor-made solution in the form of a marker, in the future, will facilitate contact with the system producer, in case of the pipeline modification or development needed.

SAVINGS

Low value of the thermal conductivity coefficient,

provides measurable savings in the process operation.The ability to self-compensate for thermal elongations.

Reduction of total assembly costs compared to traditional use pre-insulated pipes.

Ease of assembly

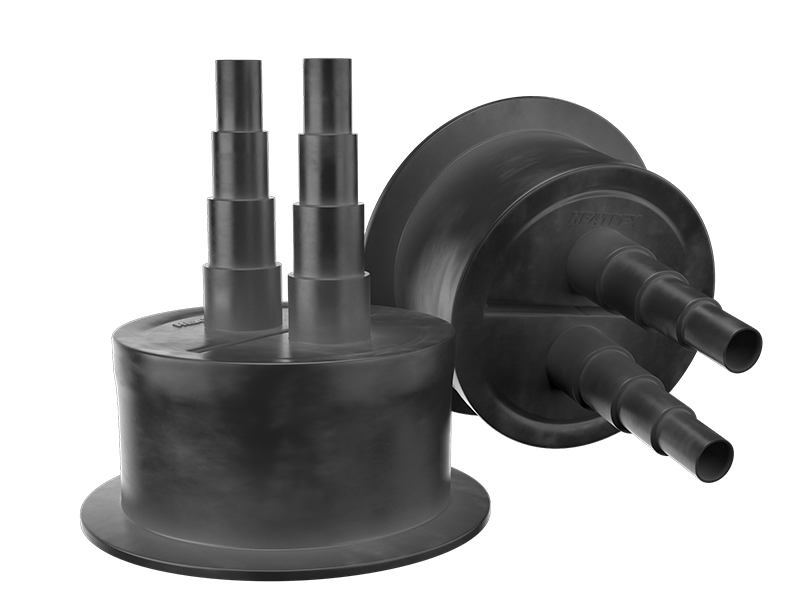

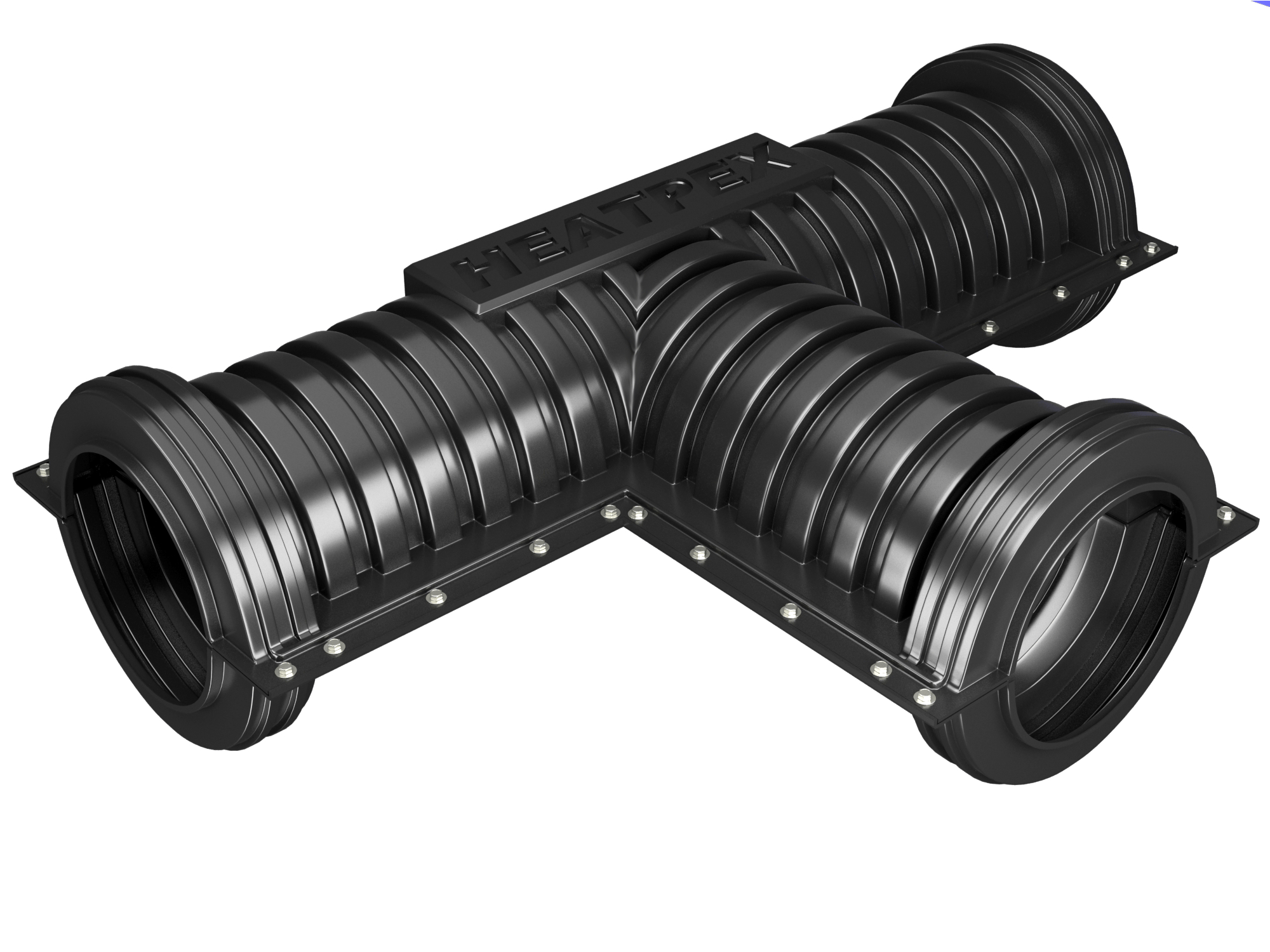

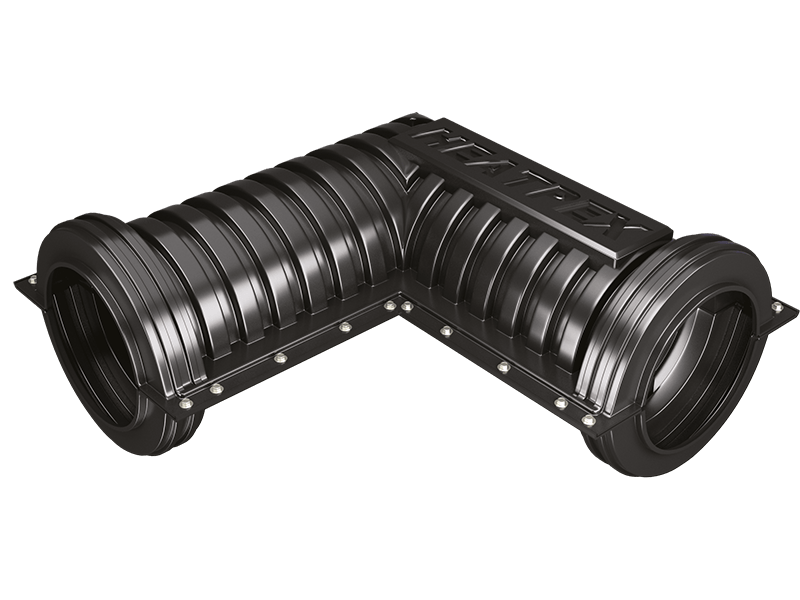

Elbows, sleeves and tees available pre-insulated to perform the necessary connections along the pipeline route allow for quick and easy to install directly in the trench.

Thanks to high flexibility and minimal bending radius from 0.25 to 1.26 m, the use of additional couplings for the obstacle avoiding during the pipeline laying process is not required.

APPLICATION

- HEAT DISTRIBUTION NETWORKS LOW TEMPERATURE PN 6/95°C SDR 11

- TRANSPORT OF WARM AND COLD TAP WATER AND DRINKING WATER PN 10/95°C SDR .7.4

- REFRIGERATION SYSTEMS DISTRIBUTION OF CHILLED WATER AND GLYCOL SOLUTIONS

- GEOTHERMAL INSTALLATIONS AS THE DISTRIBUTION OF MEDIUM FOR GROUND COLLECTORS

- TECHNOLOGICAL NETWORKS IN FOOD AND CHEMICAL INDUSTRIES